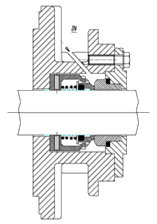

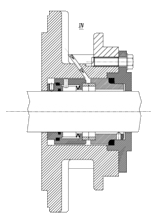

Roto Xtra Value Progressive Cavity Pumps are designed to pump ‘tough – to – handle’ fluids with ease in varied industries. The construction of these pumps is based on the modular concept and comprises of next generation pumping elements i.e. Rotor, Stator, Solid Shaft and Double Sealed Cardan Universal Joints for improved performance and longer service life.

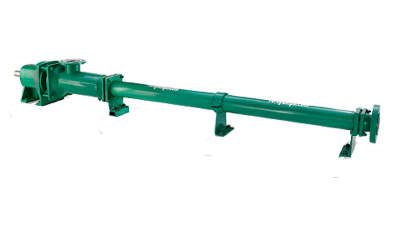

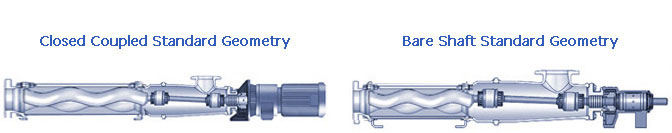

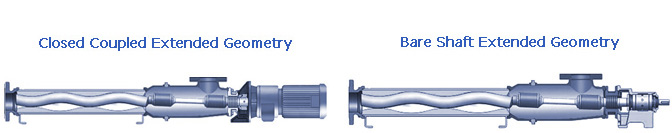

These pumps are available in bare shaft and close coupled configuration. Selected pump sizes are available with 6 stages and 8 stages.. Options also available with different material grades and shaft sealing.

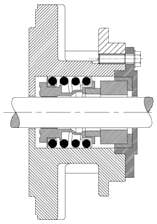

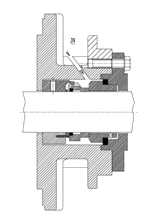

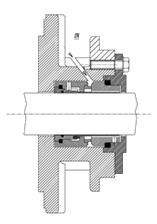

Single Stage Pump

Capacity: up to 500 m3/hr

Pressure: up to 6 bar

These Heavy Duty cost effective pumps use the extended Rotor, Stator Geometry and results in lower rubbing velocities which are ideal for various applications.

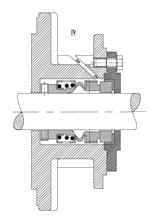

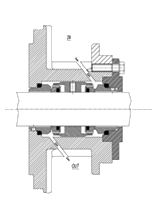

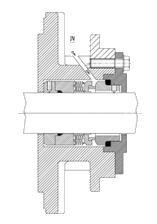

Multi Stage Pump

Capacity: up to 250 m3/hr

Pressure: up to 48 bar

These heavy duty pumps are designed for continuous or intermittent duty and are suitable to perform efficiently even for the most difficult fluid handling applications in various industries.