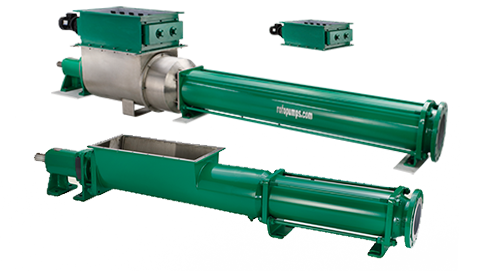

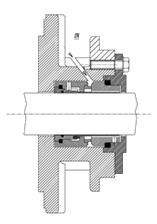

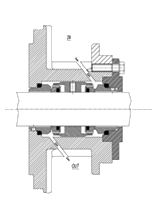

Wide Throat type inlet allows gravity flow of highly viscous (plastico – Viscous) material on to the augur-on-coupling rod which pushes the substance to the pumping element. Wide Throat Pumps with the twin paddle bridge breaker arrangement at the top are designed for handling extremely difficult media with very high solid content and non – flowing properties.

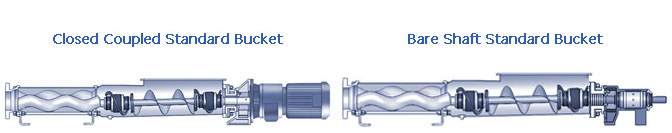

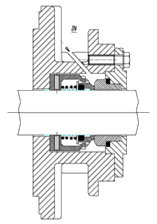

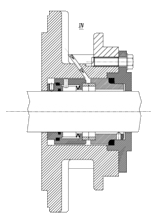

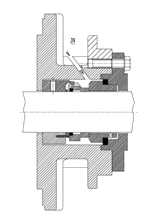

Available in close coupled and bare shaft configuration. Custom designed hopper is also available on requirement. A variety of construction materials and shaft sealing options are also available.

Standard Hopper & Oversized Hopper

Capacity: up to 200 m3/hr

Pressure: up to 36 bar