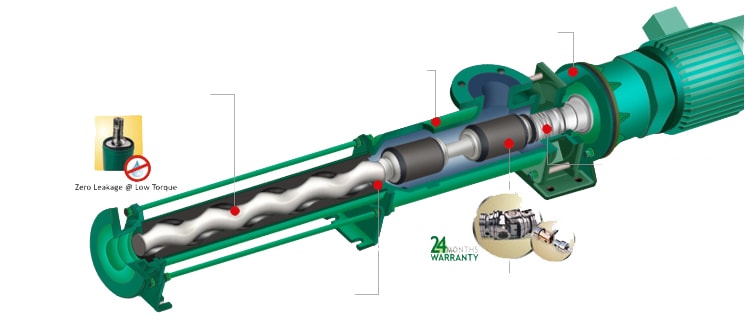

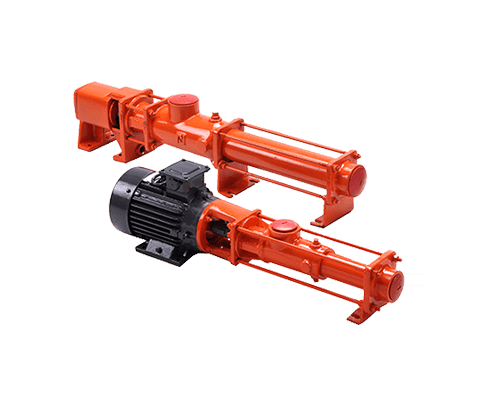

Positive Displacement

Because of single rotating element, progressive cavities are generated which deliver a uniform, metered and non-pulsating flow. The developed head is independent of the rotational speed, where as the capacity is proportionate to the speed.

Self priming

Inherently self-priming, the pumps can work on snore and do not require a foot valve.

Non-Clogging

Can handle solid in suspension or media containing a high percentage of solids.

Low NPSH Requirement

Suction lift capabilities of up to 9.5mWc and effective in high vacuum conditions.

Low Internal Velocity

Minimum degradation of shear-sensitive media, and can also handle highly viscous materials having pseudo-plastic characteristics.

Reversible

Due to the reversible rotation capabilities, Progressive Cavity Pumps can perform with equal efficiency in either direction.

Silent Running

Rotors turn inside a resilient stator and thus generate little noise.

Separate Bearing Housing

Fluids can be pumped without no contamination.