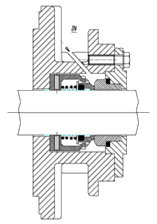

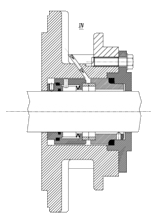

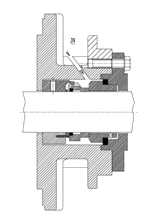

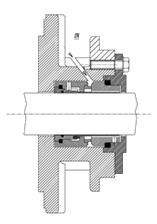

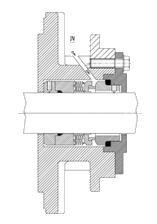

Horizontal Internal Bearing Twin Screw Pumps are selected where the fluids are clean and have lubricating properties. These pumps are designed with internal bearings which get lubricated by the pumping media itself. The suction and discharge ports are in-line.

The mechanical seals are provided as standard scope of supply. Gland packing option can also be offered as per application requirement. These pumps are fitted with relief valves and are suitable for 100% bypass. Also, these pumps are available in standard foot mounted configuration with sump heating arrangement as an option.

Internal Bearing RI Series

Capacity: up to 1000 m3/hr

Pressure: up to 40 bar

These pumps are designed for clean and lubricating media. The pumps are fitted with the bearings inside and the bearings are lubricated with the pumping media itself. They are available in standard foot mounted configuration with sump heating arrangement as an option. It is built in safety relief valve, designed for 100% bypass.